Material Categories

Explore our wide range of materials designed to meet your unique needs. While we’ve highlighted some of our most popular options, our capabilities extend far beyond this list. If you don’t see the material you’re looking for, contact us. We'll work with you to find the perfect solution.

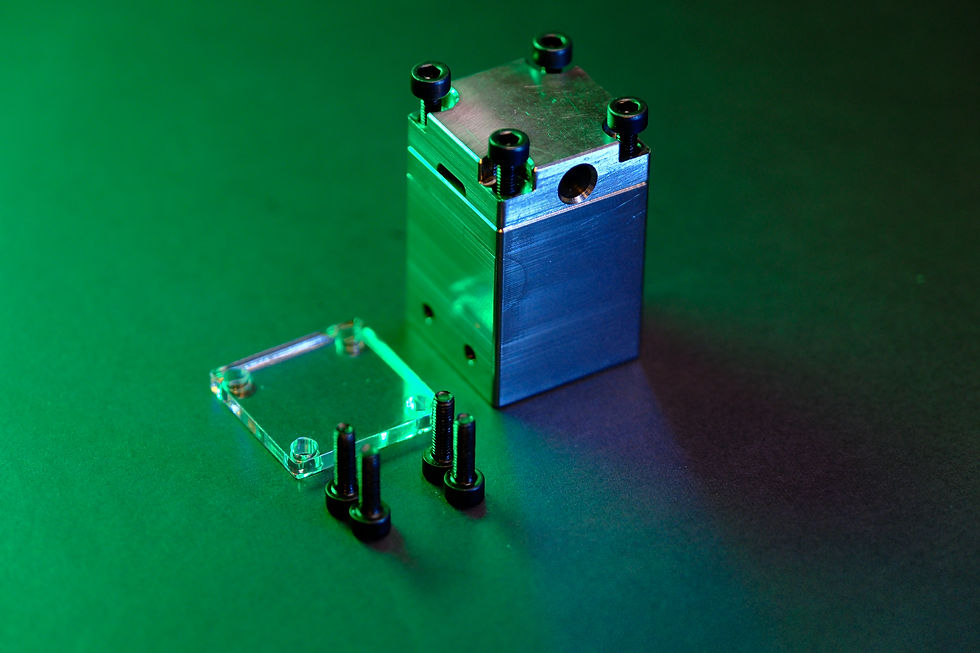

Metals

Aluminum

High strength-to-weight ratio, excellent corrosion resistance, and machinability make aluminum ideal for aerospace, automotive, and industrial applications.

1050, 1060, 2014, 5083, 5754, 6060, 6061, 6063, 6082, 7050, 7075, 7000, En AB 4700, 6062, 6068 T6, 2050 T84

Stainless Steel

Renowned for strength, rust resistance, and versatility, stainless steel is perfect for high-stress environments.

301, 303, 304, 304L, 310, 316, 316L, 318LN, 416, 420A, 420B, 420D, 440B, 440C, 15-5 PH, 17-4 PH

Brass

Offers excellent machinability and aesthetic appeal, suitable for precision parts and decorative applications.

C360, MS58, MS63

Titanium

Incredibly strong yet lightweight, titanium is widely used in aerospace and medical devices for its biocompatibility and corrosion resistance.

GR2, GR4, GR5

Copper

Exceptional electrical and thermal conductivity, making it essential for electronics and heat-transfer applications.

C10100, C14700, C14500

Tool Steel

Designed for high-wear applications like molds, dies, and cutting tools, ensuring long-lasting performance.

A2, A6, A8, 1.2363, 1.2516, 1.3501, 1.2550, D2, D3, 1.3520, 1.2419, 1.2367, 1.2379

Carbon Steel

Excellent machinability and weldability, ideal for construction and mechanical applications.

1010, 1018, S235JRC, 1020, C40, 1008, 1040, 1045, S265JR, S275JR, S355J2, C45, S355JR, 1215, API X65, 17.131

Nickel Alloys

Exceptional resistance to heat, oxidation, and corrosive environments makes nickel alloys ideal for aerospace and industrial applications.

Inconel 625, Inconel 718, Monel 400

Bronze

Highly durable with excellent wear resistance, commonly used in marine applications and decorative items.

Aluminum Bronze, Phosphor Bronze

Steel Alloys

High strength, toughness, and wear resistance; ideal for demanding mechanical, structural, and tooling applications.

4130, 4140, 4340, 42CrMo4, 41Cr4

Thermoplastics

General Use Engineering Plastics

Lightweight, strong, corrosion-resistant

POM-C, POM-H, Kestamid, PA, PA 6, PA 66, PE, PP, PET, PVC, PVC-U, HDPE, Ertacetal®, Ertalon®

Special Used Engineering Plastics

Lightweight, strong, corrosion-resistant

BASF Cellasto, PTFE, PVDF, PEEK, PMMA, PC, Divinycell® HCP50, Ertalyte®, FR-4

Composites

Carbon Fiber

Perfect for lightweight yet strong components in automotive and aerospace industries.

Manufacturing Capabilities

Rototip specializes in delivering custom manufacturing solutions to fit your unique needs. Whether you require prototypes or low-volume production, we ensure precision and quality every step of the way, offering a combination of over 10.000 materials, post processing treatments, and manufacturing methods.

All of Your Parts Come with 100% In-House Quality Control

High-Quality Post-Processes for Best Results

From surface finishes that enhance aesthetics to coatings that improve durability and custom treatments for specialized needs, our comprehensive post-processing services ensure your parts meet the highest standards. Explore our offerings below to see how we take your parts to the next level.

Coating

Protect and customize your components with durable and high quality coatings

Galvanizing

Anodizing

Powder Coating

Chemical Blackeninng

And more

Finishing

Enhance aesthetics and function with precise finishing techniques tailored to your parts

As-machined

Brushed

Bead-blasted

Polished

And more

Other

Optimize performance with our advanced treatments and personalized solutions

Laser-marking

Heat treatment

Painting

Insulations

And more

Multiple Materials, Multiple Processes: One Supplier!

Lorem ipsum dolor sit amet consectetur. Convallis convallis vulputate eget in diam. Viverra semper donec tempus lectus nunc. Pretium ornare netus tincidunt lacus. Quis id ornare mollis morbi.

_edited.jpg)

_edited.jpg)